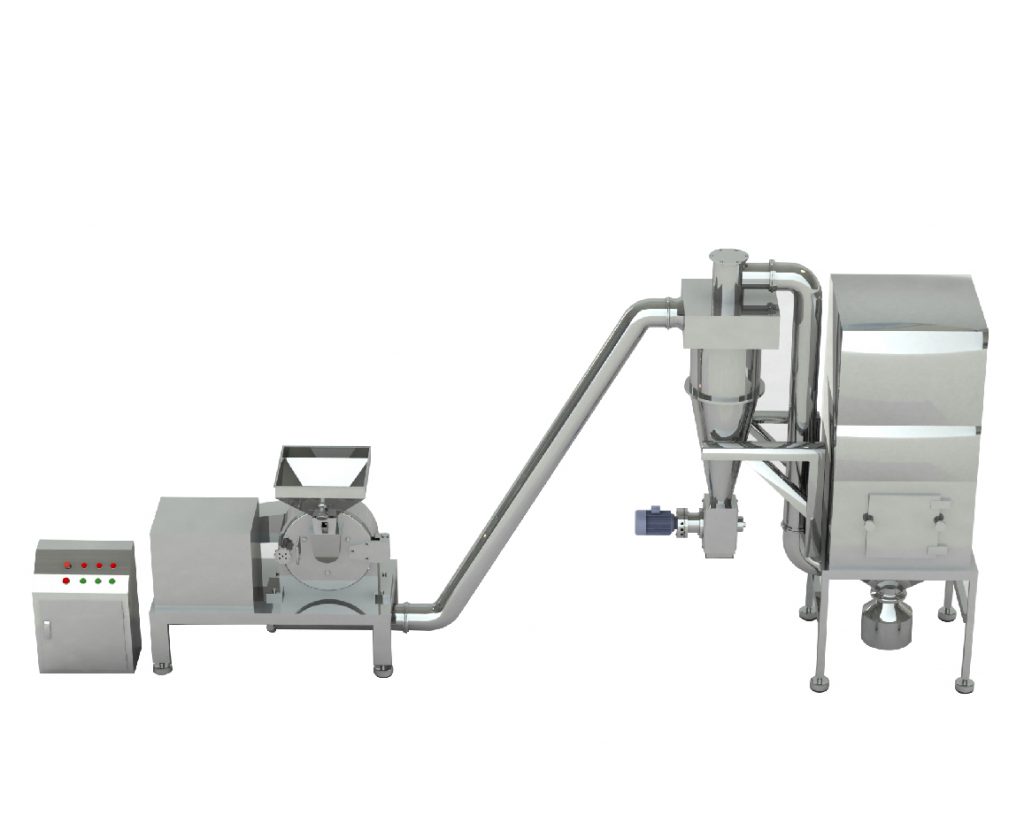

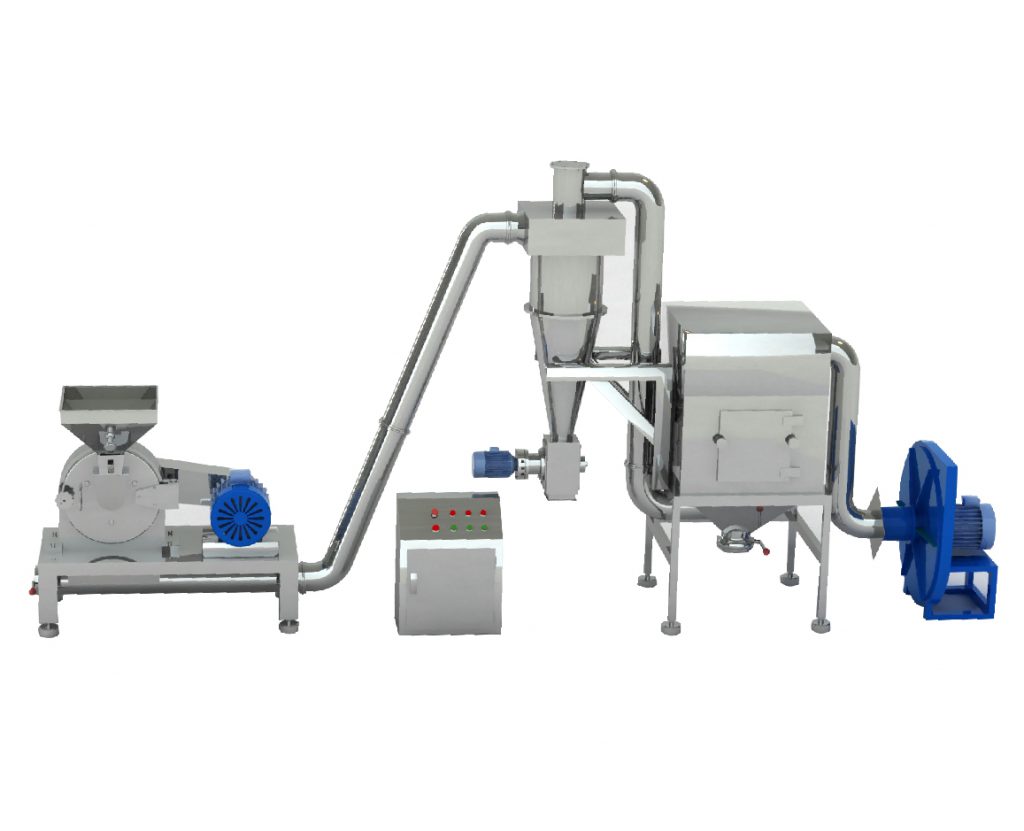

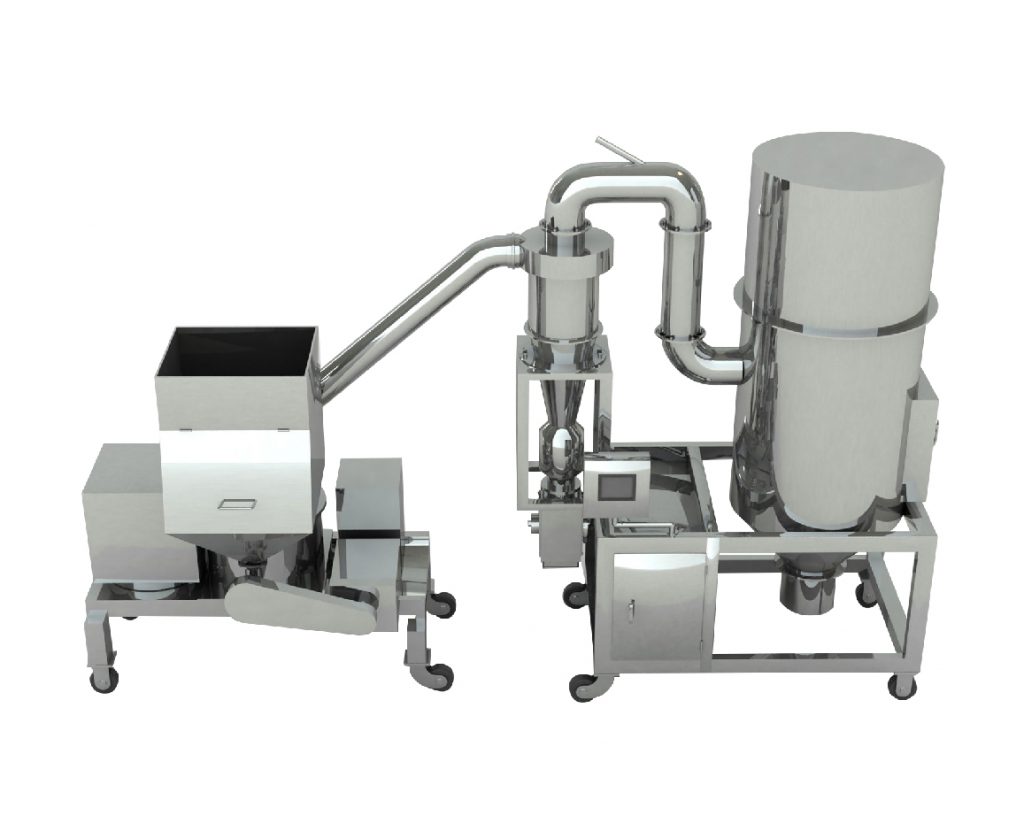

CSJ Series Coarse Crusher

Working Principle :

This machine is horizontal crushing structure, and the material is fed into the crushing chamber through a hopper, crushed by cutting and impact of both fixed and rotating knives, and flows of the exit automatically under the effect of rotating centrifugal force. Designed according to “GMP” standard and wholly made of stainless steel, this machine has simple structure, convenient cleaning and low noise, being the ideal equipment for coarse crushing.

Main Application :

This machine is applied as supporting equipment, before fine crushing process in trades such as pharmaceutical, chemical and foodstuff ect., which has better crushing effect for any material without limitation on its viscosity, hardness, softness and fiber, etc.